ZINC-PHOSPHATING FOR DEFORMATION

The traditional surface preparation methods for drawing of the carbon steel tubes are zinc-phosphating process with the subsequent saponification or application of the special lubricants.

MetalChem LTD offers the chemical materials for both mentioned-above processes.

Zinc-phosphating for drawing

Phosphating for drawing presupposes the surface processing with forming of the fine-crystalline plastic hopeit (Zn3(PO4)2 . 4H2O) layer with the optimal weight from 7 to 20 g/m2. The weight of coating mainly depends on these factors: mark of steel, parameters of the solution (total/ free acidity), choice of the accelerant, temperature, efficiency of the activation solution, processing time. The special lubricating coating based on sodium stearate is subsequently applied on this layer. The antifriction layer, that is got in the result, makes it possible to carry out the tube drawing process on XBT mills with total reduction to 50% and surface roughness Ra about 0,4 - 0,9 µm (7-8 surface finish class).

In general phosphating technology is showed in table 1.

Table 1

|

№ |

Process |

Product |

T, °C |

|

1 |

Degreasing |

MetaDip line |

50-60 |

|

2 |

Rinse |

Tap water |

20-40 |

|

3 |

Etching |

H2SO4 or HCl with pickling inhibitor |

40-90 |

|

4 |

Rinse |

Tap water |

20-40 |

|

5 |

Rinse |

Tap water |

60 |

|

6 |

Activation |

MetaCond line |

40 |

|

7 |

Zinc-phosphating |

MetaPhos line |

60-80 |

|

8 |

Rinse |

Tap water |

20-40 |

|

9 |

Neutralization |

Meta N line |

40-60 |

|

10 |

Saponification |

MetaLube line |

60-70 |

Comments to table 1

1) Etching with application of the inhibitor. Inhibitor purpose: optimization of the etching process, that is: decrease of the acid influence on metal, increase of etching solution service, minimization of spot corrosion.

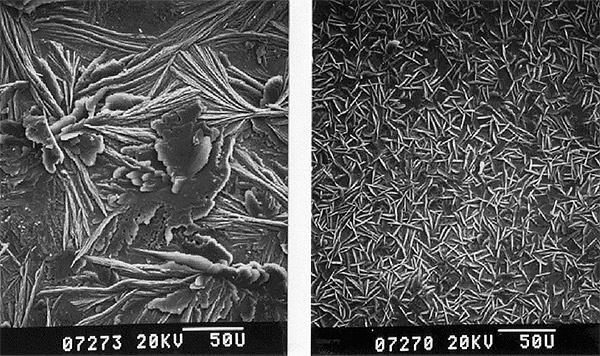

2) Activation. Application of the activating composition of MetaCond line leads to forming of crystallization sites on the surface. This stage is extremely important for the subsequent growth of crystals with forming of the fine-crystalline uniform phosphate coating and accelerating of the phosphating process.

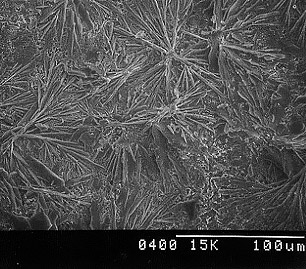

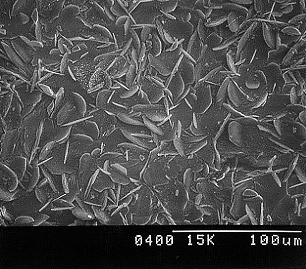

On the left picture it is showed the appearance of phosphate coating without activation, on the right - the coating after activation in the solution on MetaCond base.

3) Zinc-phosphating.

As stated above, the optimal coating for drawing is the layer with the weight from 7 to 20 g/m2. The compositions of METAPHOS line with different accelerant types are applied to form such layer:

- Nitrate; NO3- + 2HO → NO2- + H2O (→ nitrite)

- Nitrite; NO2- + 3HO + H+ → 1/2 N2 + 2H2O (→ nitrogen)

NO2- + 6HO + 2H+ → NH4+ + 2H2O (→ ammonium)

NO2- + HO + H+ → NO/NO2/N2O3 + H2O (→ nitric oxide)

NO2- + H2O → NO3- + NO2- (→ Nitrate, nitrite)

- Chlorate ClO3- + 6HO → Cl- + 3H2O (→ Nitrate, nitrite)

- Peroxide 2H2O2 → 2H2O + 2O (→ Oxygen)

- M-nitrobenzosulphonate

- Hydroxylaminosulphate (NH3OH)2SO4

- Without accelerant with buffer additive

The choice of certain accelerant is defined by the requirements and manufacturing capability of the customer.

Table 2

The comparison of phosphating processes with different accelerants (averaged data)

|

|

Phosphating time (min) |

Temperature (°C) |

Coating weight (g/cm2) |

| ClO3- |

5-8 |

60-70 |

8-12 |

|

NO2- / NO3- |

4-10 |

60-70 |

8-10 |

|

ClO3- / NO3- |

5-6 |

60-70 |

7-12 |

|

Without accelerant with buffer additive |

4-10 |

50-65 |

5-20 |

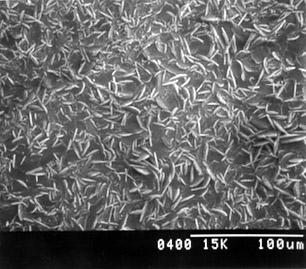

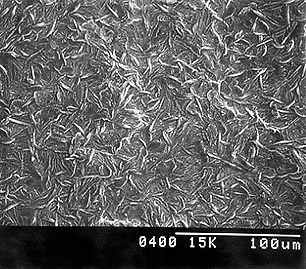

The pictures of the layers, that were got after phosphating with application of some mentioned-above accelerants, are showed below.

Chlorate-Nitrate Chlorate

Without accelerant Nitrate-Nitrite

with buffer additive

For further information or technical offer on the above-mentioned materials and processes contact the Technical Service.

MetalChem company provides its customers technical support during developing of the technologies, tests and also ensures regular technical service during the whole period of applying its materials.